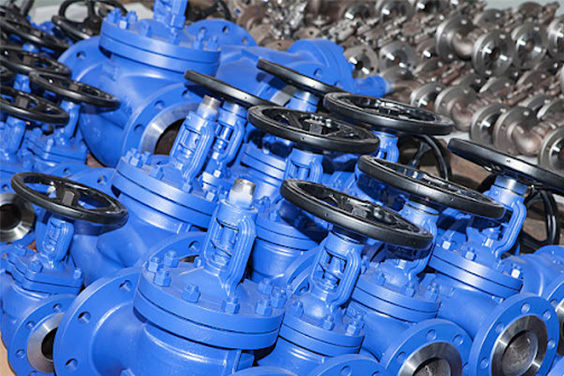

The ball valve is the most common type of valve used in various industries. There is a growing demand for ball valves. People may have wondered what impact ball valves can make on application. This article will explain the main components and their respective functions. We will also show how the ball valve works to better understand its function before purchasing one for applications.

What Is a Ball Valve?

A ball valve is a piece of simple yet essential equipment in many industries. It is a quarter-turn valve, which can be turned up to 90 degrees to open or close. The pneumatic ball valve working allows or blocks the flow of fluid in a piping system. When the handle is turned to the open position, the ball is turned so that the two ports are aligned, allowing fluid to flow through. When the handle is turned to the closed position, the ball is turned so that the ports are misaligned, and fluid is blocked.

Benefits Of Using Ball Valves

Ball valves are a type of valve that is commonly used in a variety of industries. They are known for their durability and reliability and can handle a wide range of temperatures and pressures. Ball valves are also relatively easy to operate and maintain, which makes them a popular choice for many businesses.

There are many benefits of using ball valves, including:

- Ball valves are very versatile and can be used in various applications.

- Ball valves are easy to operate and can be opened and closed with little effort.

- Ball valves are durable and can last for many years with proper care.

- Ball valves are very reliable and can be used in critical applications.

- Ball valves are very cost-effective and can be an excellent value for the money.

Cons Of Using Ball Valves

Here are some cons of using ball valves, including:

- Ball valves can be prone to leaking.

- Ball valves can become stuck in the open or closed position.

- The ball in a ball valve can rust over time.

- Ball valves can be more expensive than other types of valves.

- Ball valves may not be appropriate for some applications.

Applications of Ball Valves

A ball valve is a type of valve that is used in a variety of applications. Here are 5 of the most common uses for ball valves:

- To regulate the flow of water in plumbing and irrigation systems

- To control the flow of oil and gas in pipelines

- To act as a shut-off valve in chemical plants and refineries

- To regulate the flow of air in pneumatic systems

- To control the flow of steam in heating and cooling systems

Working Principle Of Ball Valve

The working principle of ball valve is the same as the butterfly valve. It is composed of a ball with a borehole in the middle. The flow will open or close depending on the position of the hole. The stem is attached to the ball, which in turn is connected to either the twisting handle or actuator.

The following is ball valve working principle:

The actuator rotates counterclockwise at around 90 degrees to initiate the flow of fluid. It turns the stem when it rotates. The stem rotates the ball. The flow begins through the valve when the ball’s hole is in line with the fluid flow. The actuator spins counterclockwise around 90 degrees and turns the stem in an anticlockwise direction to block the fluid flow. The fluid flow is stopped completely when the ball rotates anticlockwise 90 degrees. The ball is kept open to partial and closed conditions for throttling flow. The smooth seats could be permanently locked if the valve is left partially open for too long under high-pressure drop conditions.

Parts Of A Ball Valve

Many types of ball valves are available, including 3-way and ball valves made from different materials. The 3-way ball valve working mechanism differs from the standard ball valve. There are many ways of classifying valves. Regardless, there are seven components that all valves share.

- Body

The body is the structure of the complete valve. It prevents pressure transfer to the pipes by acting as a hindrance against the pressure load from the media. It comprises all elements jointly. The body connects to the piping through joints that can be threaded, bolted, or welded. The type of ball valve can be classified based on the body. These are usually cast or forged.

- Stem

The stem is responsible for opening and closing the valve. The stem is attached to the handle, lever, or actuator to the balling disk. This is the part that revolves around the disc opening and closing.

- Packing

This gasket seals the bonnet and stem. This is where many problems occur, so it is crucial to do a proper installation. Leakage can occur if the stem is too loose. Too tight, and the stem will not move.

- Bonnet

The bonnet covers the outlet of the valve. The bonnet works as a secondary fence to pressure. After all internal components are installed inside the valve body, the bonnet holds them together. The bonnet is often made of the same material as the valve body. It can be either forged or cast.

- Ball

It is the kind of disc that houses the ball valve. The pressure boundary of the media is the third most important. It works against the disc in its closed position. Many ball discs are made from forged steel or other durable materials. The ball disc can be suspended as in the case of the floating valve or mounted like the trunnion-mounted ball valve.

- Ball

It is the kind of disc that houses the ball valve. The pressure boundary of the media is the third most important. It works against the disc in its closed position. Many ball discs are made from forged steel or other durable materials. The ball disc can be suspended as in the case of the floating valve or mounted like the trunnion-mounted ball valve.

- Actuator

Actuators are instruments that produce the rotation required by the ball valve in order to unlock the disc. These devices often have a power source. The remote control is possible for some actuators so that valves can still be operated even though they are in difficult to reach or remote locations.

Handwheels can be used to operate manually utilized ball valves. Other actuators are solenoid types, pneumatic types, hydraulic types, and gears.

Materials Used for Ball Valves Construction

Different materials are used for ball valve construction based on the operating conditions, the type of ball valve, and the end use. One of the most crucial selection considerations is the material’s compatibility with the process fluid. Other considerations include corrosion resistance, abrasion resistance, and material strength.

The most common materials for ball valve construction are stainless steel, brass, bronze, and plastic. Stainless steel is popular because it is corrosion resistant and can withstand high temperatures. However, it is also one of the more expensive materials. Brass is another popular choice because it is less expensive than stainless steel and has good corrosion resistance. However, brass is not as strong as stainless steel and can deform over time.

Bronze is another option for ball valve construction. It is solid and durable, but it is also susceptible to corrosion. Plastic is the least expensive option, but it is not as strong as metal and can be easily damaged.

Bottomline

In this article, we have discussed how does a floating ball valve work. The ball valve is widely used in the industry due to its simplicity and reliability. It consists of a ball with a hole in the centre connected to a rod. When the rod is turned, the hole is aligned with the inlet and outlet, allowing flow through the valve. Ball valves are durable and have a long service life. Please contact us for any further questions about ball valves or would like assistance selecting the correct valve for applications. Dombor is one of the best valve manufacturers in the world.