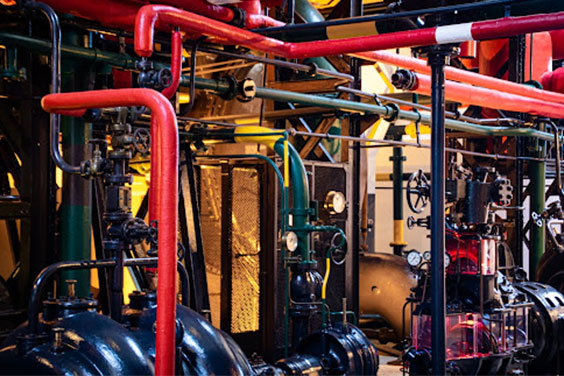

Butterfly valves are a regular part of any industry – be it for domestic use or applied in industrial conditions, there are several uses for butterfly valves. There are a few basic types of industrial valves, like butterfly valves, ball valves, check valves, etc., and these are commonly found in many industries.

Qualified industrial valves manufacturers specialize in a variety of valves like the ones given above. Butterfly valves, a common industrial valve, are usually found in waste management systems, oil and gas refinery and others. This article explores more about what is butterfly valve and its working principle.

What is a Butterfly Valve?

One of the commonly used industrial valves is the butterfly valve – a member of the quarter-turn valve family, this valve is usually employed to stop and start the flow of media in a pipeline. While these valves can be used for regulating media flow, they face severe damage, so it is not widely advised.

Butterfly valves are quarter-turn valves, just like industrial ball valves – meaning, when these valves are turned 90°, they either completely stop or let the media flow. As these valves are built in a simple design, they are light and compact. Complete closure or opening of the valve can be obtained in 90° turns, but to regulate the flow, the valve should not be turned fully.

Using the valve for regulating purposes can cause its sealing property to become questionable. Also, the valve disc gets damaged when used for regulating, so these valves are often used as on-off valves. The advantages of using a butterfly valve include fast actuation and lower costs.

Butterfly valves arrive in many types – triple offset butterfly valves, wafer butterfly valves, and flange butterfly valves are some of the common ones.

Parts of a Butterfly Valve

While most industrial valves share common parts, specific types of valves have unique parts and features. Here are some of the common parts found in a butterfly valve:

Valve Body

The valve body contains the different parts of the butterfly valve. There are primarily two types of valve bodies – wafer-style and lug body.

The wafer-style body has a simple design compared to the lug body type – for connecting the pipes, the body features bolt holes that are found throughout the body. Commonly used in systems that require the prevention of backflow, this body type is not suited for regulated systems.

On the other hand, the lug-type body in a butterfly valve is all about external connection with pipes. Instead of featuring holes inside the valve body, this design has protruding lug holes on the outside. Although this valve body type is a bit more complex, it boasts its own advantages.

Disc

The disc is the part of a butterfly valve that is responsible for controlling flow. It is attached to the valve body and is similar to the structure of a gate in a gate valve. While there are many variations in the design of a disc based on its applications, the common variants include eccentric and concentric. It is crucial for a butterfly valve to have a rigid disc so as to ensure that the flow is throttled precisely.

Seat

The seat is the component of a wave that holds the disc in its place – the seat of a valve is made from strong elastomers to ensure that it does not leave its position. One should also note that the seat is not a small part of the butterfly valve, but rather runs throughout the inner lining of a valve. Elastomers are used for the production of these parts because they help in retaining the tightness of the seal between the seat and the disc.

Stem

If the butterfly valve is actuated manually, then a mechanism should connect it to the disc so as to throttle it. The stem, or the valve shaft, is the unit that connects the actuation mechanism and the disc. There are two types of stems – wetted and non-wetted.

Seals

Present at multiple places inside the butterfly valve, the seals ensure that there is no air leakage and the valve is shut off tightly. A faulty seal can cause fatal damage to the working of a butterfly valve, so it is an important part of the valve.

How does a Butterfly Valve Work?

As stated before, butterfly valves are quarter-turn valves that are best used for the stop/start of media flow in pipelines. When the valve handle is turned 90°, it either opens or closes completely. Throttling can be a bit tough, but these valves can still be used for regulating purposes.

A butterfly valve can be either operated manually, pneumatically, or electrically through an actuator. Using the actuator can help in controlling the valve – the actuator will be connected to the disc and it will move the disc according to the required operation.

For each type of operation, there is a particular kind of tool that helps in the actuation. For example, pneumatically controlled butterfly valves have a piston attached to them. Technically speaking, this is the best method to control a butterfly valve as it enables quick shut-off and turn-on capacity.

Butterfly valves are usually installed in a fully open position. This is because installing the valve in its closed position can cause difficulties with the seat and seal positions.

What is a Butterfly Valve Used for?

Butterfly valves are specifically used in fluid storage and transportation as these valves are good at handling media like slurry. Butterfly valve manufacturers take into consideration quality, techniques, material, and other such values to manufacture butterfly valves with specific purposes. There are three main functions that these valves serve:

- Flow Regulation: While butterfly valves are not the best choice for flow regulation, they still can be used for this purpose. By attaching an automated valve actuator, the flow of the medium can be regulated through a butterfly valve.

- Flow Isolation: Butterfly valves make a great option for the purpose of flow isolation as they have a quick shut-off quality. These valves have a compact and light build that enables them to be operated easily. These valves also enhance pressure recovery and limit pressure drop.

- Stop/Resume Flow: Butterfly valves are best used for stopping and resuming the flow of media in piping systems. Their quick-shutoff quality enables them to stop or resume flow in a pipeline.

- Backflow Prevention: In specific situations, butterfly valves can be used for the prevention of backflow. These valves are mostly used in such situations in wastewater facilities.

Applications could include:

- Wastewater treatment

- Oi l& Gas industry

- Chemical industry

- Pipeline transport

- Marine industry and so on

Contact the Best Valve Manufacturer in China

Butterfly valves are one of the most commonly used industrial valves in many industries including wastewater treatment plants. If you are looking for a qualified valve manufacturer in China, then DomBor is the right solution for you. We specialize in a wide range of industrial valves including ball valves, butterfly valves, check valves, and gate valves. Get in touch and find a quote for your project with us today!