What are Cryogenic Valves?

Often in chemical and LNG (liquefied natural gas) industries, pipelines and valves are involved in the transmission of cryogenic liquids and gasses. These are some cryogenic valves applications. Cryogenic valves are specially designed valves that are made to be employed in situations like these. Cryogenic refers to materials and fluids that are handled below -101℃, i.e., -239℉, so these valves must be produced from materials that will withstand these extreme temperature ranges.

Cryogenic valves are not just the ones that work well under low temperatures – valves that handle fluids with high pressures are also known as cryogenic. In general, a cryogenic valve will be able to handle fluids with temperatures as low as -320℉ and pressure as high as 750 psi (pound per square inch).

Features of Cryogenic Valves

Cryogenic valves and standard valves used in normal temperatures have several different characteristics. Here are a few stated:

- Cryogenic valves are capable of handling temperatures ranging from 37℉ to -320℉. The temperature range varies from one valve to another.

- Usually, cryogenic valves are designed to have long stems. This is because the valve stem seal should be kept away from the cold fluid.

- Cryogenic valves have excellent bubble-tight shutoff features to prevent leakage at any cost. As the fluids transported in these valves and pipelines are chemicals, leakages can cause extreme results.

- Cryogenic valves are specifically employed in chemical, LNG, CNG, and other oil and gas industries.

- Compared to standard valves, these valves are light. Also, they should be very clean and lubricant-free.

How do Cryogenic Valves Work?

Cryogenic valves are used for storing and transporting cryogenic liquids and gasses like liquid oxygen, liquid hydrogen, liquified natural gas, liquified petroleum, etc. The working of a cryogenic valve is somewhat dependent on the external pressure. The standard position in which a cryogenic valve is maintained is the closed position. This will ensure that the media inside the valve stays put and does not escape into the atmosphere.

These valves are designed expertly to react when pressure increases. When the pressure rises, it pushes the valve into the open position, and hence the media flows. This flow will continue till the pressure dwindles.

Design

Cryogenic valves are manufactured from special materials like LCB, LC3, CF8, etc. The material of the valve will be chosen as per the temperature range the valve can withstand. If the valve is not produced from a suitable material, then the design will lead to internal and external leakages, cracks, and other major issues.

The main design aspect of the cryogenic valve that stands out from an industrial valve is the extended stem. This stem is designed to keep the external heat out and the packing gland at temperatures above 0°C. Also, the stem ensures that the parts above the bonnet of the valve do not get frozen.

Impressive Sealing

The reason why these valves have extreme sealing properties is because of the media they carry. Leakage of some chemicals stored in a cryogenic valve can cause disastrous results – many chemicals are inflammable at higher temperatures.

Also, another major issue with the rise of temperature in valves is the phenomenon of gasification. If the fluids inside a cryogenic valve gasify, then the volume of the fluid will increase ten and hundred folds, causing a blast in the pipeline.

Challenges

When a cryogenic valve is not designed as per standards, there are high chances that the valve will cause extreme risk. Several factors like external heat, pressure, and other dangers always pose a challenge for cryogenic valves, so it is of utmost importance that these valves are made of quality materials.

A few standards and codes for cryogenic valves include – BS 6364, MSS SP-134, ISO 28921-1, and ASME B16.34.

Types of Cryogenic Valves

Not all types of standard valves can be used as cryogenic valves. Generally, ball, butterfly, globe, and relief valves are used as cryogenic valves. Also, quarter-turn valves are given more preference because of their right shut-off capacity.

- Cryogenic Ball Valves

A valve that belongs to the quarter-turn family, the ball valve is a great choice for cryogenic fluid transport and storage. This is because the valve has great flow characteristics and excellent shut-off quality.

- Cryogenic Butterfly Valves

Cryogenic butterfly valves have a shorter length compared to other cryogenic valves because of the circular disk at the center. This range is cheaper and lighter compared to others, and it also provides quick opening and closing actions.

- Cryogenic Globe Valves

Globe valves contain an internal disk that rotates perpendicularly to the seat of the valve. A cryogenic globe valve offers long-term operation and durability. Also, these valves offer long-lasting sealing.

- Cryogenic Gate Valves

In a gate valve, there is a structure that can be lowered to stop the flow of media. The gate obstructs the flow and can be lifted to resume flow. The cryogenic gate valve is similar to the ball valve variant – enduring with a tight shut-off capability.

- Cryogenic Relief Valves

Cryogenic relief valves are a perfect option for many industries as they work based on pressure differences. These valves maintain a particular range of pressure inside a pipeline and prevent over-pressurization. When a certain limit of pressure is exceeded, these valves let out the pressure by themselves.

Common Cryogenic Valves Applications

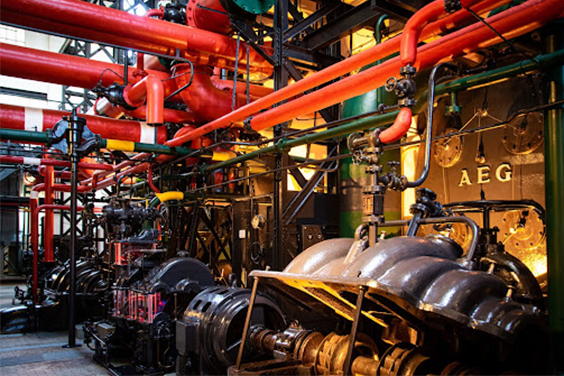

Mainly, cryogenic valves find applications in the oil and gas industry, but there are other industries and sectors that employ these valves. Here are some of the common cryogenic valves applications:

- LNG Plants and Terminals – Liquefied Natural Gas (LNG) can only be effectively transported through cryogenic pipelines and valves because the liquid has a high risk of vaporizing and expanding with pressure. Based on the requirement, the right type of cryogenic valve can be chosen.

- Food and Beverage Industry – Cryogenic Valves find wide applications in factories that deal with processed food items and beverages. These items are transferred to and from a freezer using cryogenic pipes and valves.

- Chemical and Petrochemical Industry – In the chemical and petrochemical industries, the need to transport liquified gasses and other chemicals arises. These are done with the help of cryogenic valves.

- Aerospace Storage – Used throughout constructions and turbines, cryogenic valves are a common sight in the aerospace industry.

- Medical Industry – The scope of cryogenic valves are ever expanding and they are even employed in the medical industry. They can be found in pipelines transmitting gasses like oxygen and also in storage spaces that house medical instruments.

- Air Separation Plants – To separate the different gasses in the air, several pressure techniques are used. Cryogenic valves find great applications in these plants.

Conclusion

The cryogenic valves applications are spread far and wide – as these valves specialize in dealing with fluids at extremely low temperatures and high pressures, they are suited for many industries and sectors.

When choosing a cryogenic valve manufacturer, it is important to look for the materials they use to manufacture these valves. Also, certain certifications are mandatory for the production of these valves. DomBor is one of the leading manufacturers of cryogenic valves and has been supplying valves to several industries for the past two decades.

Get in touch with us today and choose the perfect cryogenic solution that will fit your needs.