Industrial valves are found everywhere – be it in an industrial setting or a domestic setting, valves play a crucial role in making our everyday lives easier. Globe valves are one of the most common industrial valves that are commonly found in steam services, oil and gas pipelines, turbine seals, and boiler vents.

This article will give detailed explanations of what a globe valve is, the parts of the valve, and how it works.

What is a Globe Valve?

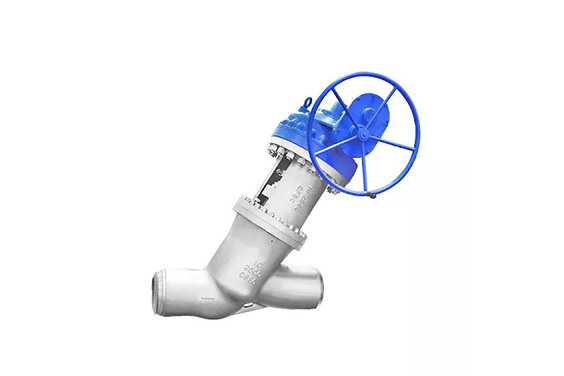

A globe valve is an industrial valve that is designed to stop, start, or regulate flow. It is a linear motion valve where the internal disc can be adjusted to tinker with the flow of media – this assures the complete flow or obstruction of a particular medium.

Unlike a few other industrial valves, globe valves are ideal for throttling and controlling flow. Globe valves can also be used for the isolation of media. They are mainly employed in small piping systems to ensure complete control over the flow of a medium.

The main working principle of a globe valve involves the movement of a disc that acts as the closure member. By moving the disc in or out of the seating surface, one can control the movement of media in a pipeline. These valves form a cavity – a globular-shaped cavity – around the port region, and hence they acquire the name.

A qualified globe valve manufacturer will consider a multitude of factors like pressure drop, frequency of usage, and the choice of media before designing a globe valve.

Types of Globe Valves

Globe valves feature a stem that moves up and down – this ensures the flow of media inside the valve. They also feature a seat that is structured parallel to the flow. Based on the position of the seat, stem, and disc, one can find different types of globe valves.

There are three main types of globe valves – the standard or T-type globe valve, the angle globe valve, and the Y-pattern globe valve. Let us see what are the structural differences between each type of globe valve.

T-Type Globe Valve

T-type is one of the most commonly found types of globe valves, and in it, the seat is placed horizontally – this means that the stem and disc travel perpendicular to the seat. This design of a standard globe valve is preferred often because it exhibits the lowest coefficient of flow along with the highest pressure drop.

This globe valve variant is a good option in cases where the pressure drop is not a problem. They are perfect for high-throttling services because of their design.

Angle Globe Valve

These valves are a slight variation of the standard T-type globe valve. Here the ends of the valve are at a 90° – this allows the fluid inside the valve to flow in a single perpendicular turn. Compared to Y-pattern globe valves, these valves possess a slightly lesser coefficient of flow.

These valves are capable of handling the slugging effect, thus they are often used in places where the flow is pulsating.

Y-Pattern Globe Valve

Given that globe valves are usually found with a high-pressure drop condition, these Y-pattern or Wye pattern globe valves act as alternatives. The seat and stem, usually found perpendicular to each other, are built at an angle of 45°. These valves can be kept open for a long time without the fear of corrosion.

When in the open position, the angle of this valve offers a straighter pathway for the flow of media. This valve also offers the least resistance during flow.

Parts of a Globe Valve

Like any other industrial valve, a globe valve features three main parts – disc, seat, and stem.

- Disc

Again, there are three types of discs when it comes to globe valves – conventional disc (ball disc), composition disc, and plug type disc.

Built earliest, the ball-type disc is made of metal in a ball shape and is fitted against the flat seat of the valve body. A globe valve with a ball disc should be conventionally used for low-pressure situations where intense throttling is not expected.

In the composition disc, a non-metal ring is used on the disc – this is done so that tighter closure can be obtained. The valves with composition discs are capable of tight sealing but they do not damage the valve in itself. Commonly used in steam and related applications, these discs are resistant to erosion.

As for plug-type discs, it is the best option for applications that demand high throttling. Long and tapered, these discs are available in many shapes and the surface of the discs is not affected by foreign material easily.

- Seat

The seat of a globe valve can either be integrated into the body or can be screwed in. some globe valves also feature a backseat inside the bonnet of the valve – this acts as a seal between the seat and bonnet and consequently prevents the building of pressure,

- Stem

The disc and the stem inside the valve are connected in two ways – either the T-slot or the disc nut construction.

How Does a Globe Valve Work?

To understand the working of a globe valve, one should understand how the disc and seat of the valve are positioned. The disc inside the valve is movable whereas the seat is stationary and is in a spherical body. The seat is parallel to the pipe and perpendicular to the disc.

The disc of the valve will move up and down according to the actuation of the wheel on the top of the valve. The wheel can be moved either manually or through an actuator – when it is moved, the disc rises and falls as it is attached to the valve stem. To stop the flow completely, mpletely, the disc is fully seated on the seat ring. To resume flow, the disc is lifted up.

Throttling and controlling of flow can be done by adjusting the position of the disc as per need.

If the case is so that the globe valve is operated in low-temperature situations, then the valve is installed in such a way that the pressure falls under the disc. For high-temperature situations, like boilers that work in steam, the valves are positioned to handle pressure above the disc.

What is a Globe Valve Used for?

- Shut-off Capability – Globe valves are mainly used for their excellent shut-off capabilities. The discs present in globe valves ensure tight sealing properties, making them a perfect choice as oil valves.

- Throttling – Surprisingly, globe valves also make a good choice for throttling and regulating flow. The wheel of a globe valve enables the user to adjust the disc as per need and achieve the right amount of throttling easily.

- Pressure Relief – In some cases of special construction, globe valves can be used as pressure relief valves and check valves.

Contact the Best China Valves Manufacturers Today

Globe valves are widely employed in many industries such as oil and gas, cooling systems, boilers, and many others. If you are looking forward to choosing the right type of industrial globe valves for your project, then DomBor is the perfect choice for you. As one of China’s leading valve manufacturers, we specialize in a variety of globe valves. Contact us today and get a quote for your project to know more!