Valve fault description

The valve seat of the bottom discharge valve of paste resin device in resin workshop has accumulated material, and the sealing effect cannot be achieved by closing the valve.

Inference of the cause of the problem

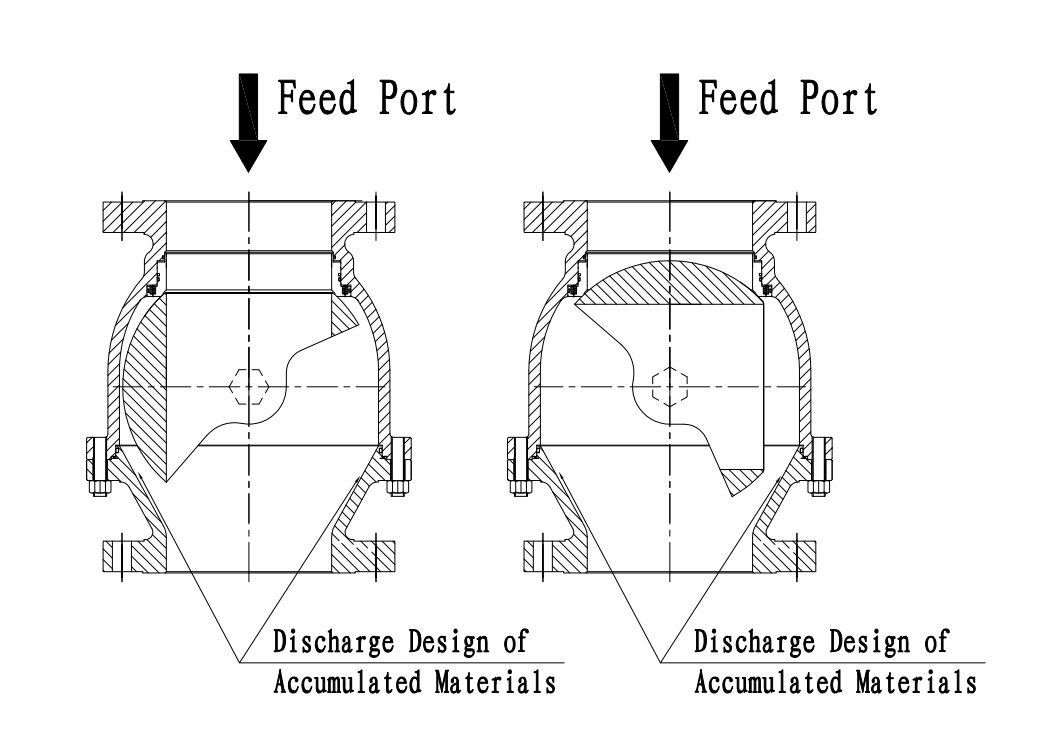

During the opening and closing process of the valve, particles in the medium will enter the valve cavity. The hair cavity is a relatively closed space, and the particles accumulate and accumulate for a long time, forming massive solid agglomerations in the photos, resulting in the ball being held up by agglomerations, which can not be in close contact with the sealing surface of the valve seat, and the valve is not normally sealed.

Problem solution

In the process of valve opening and closing, it is inevitable for the medium particles to enter the valve cavity. If the particles in the valve cavity can be discharged smoothly, the problem can be solved.

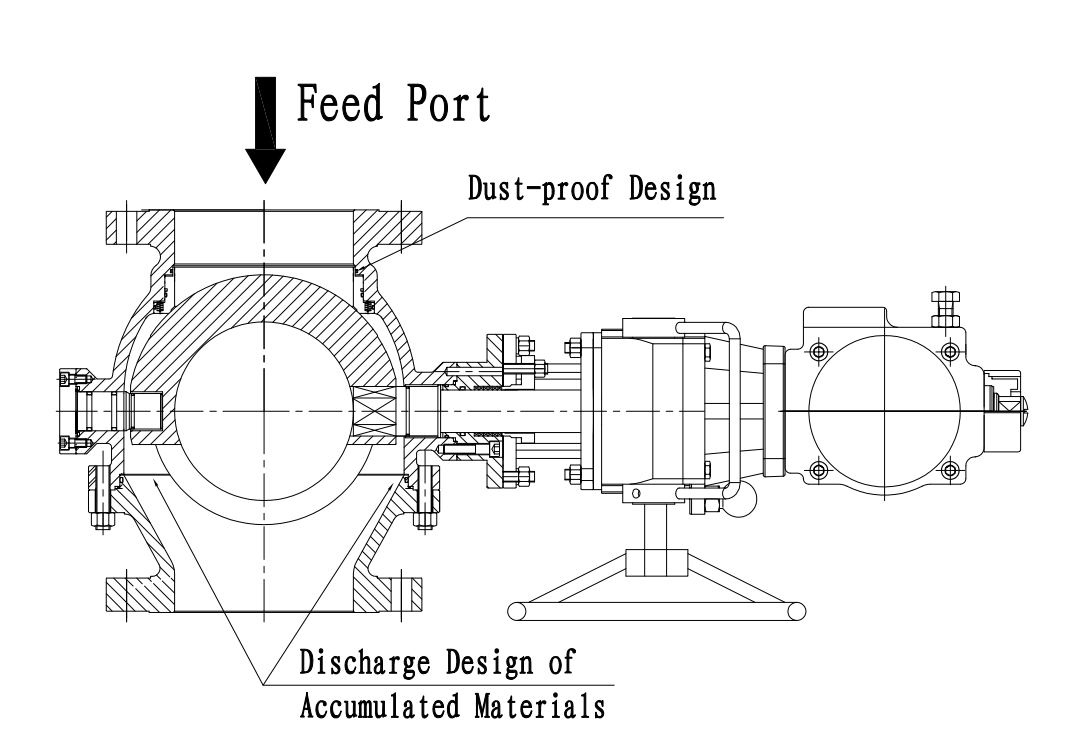

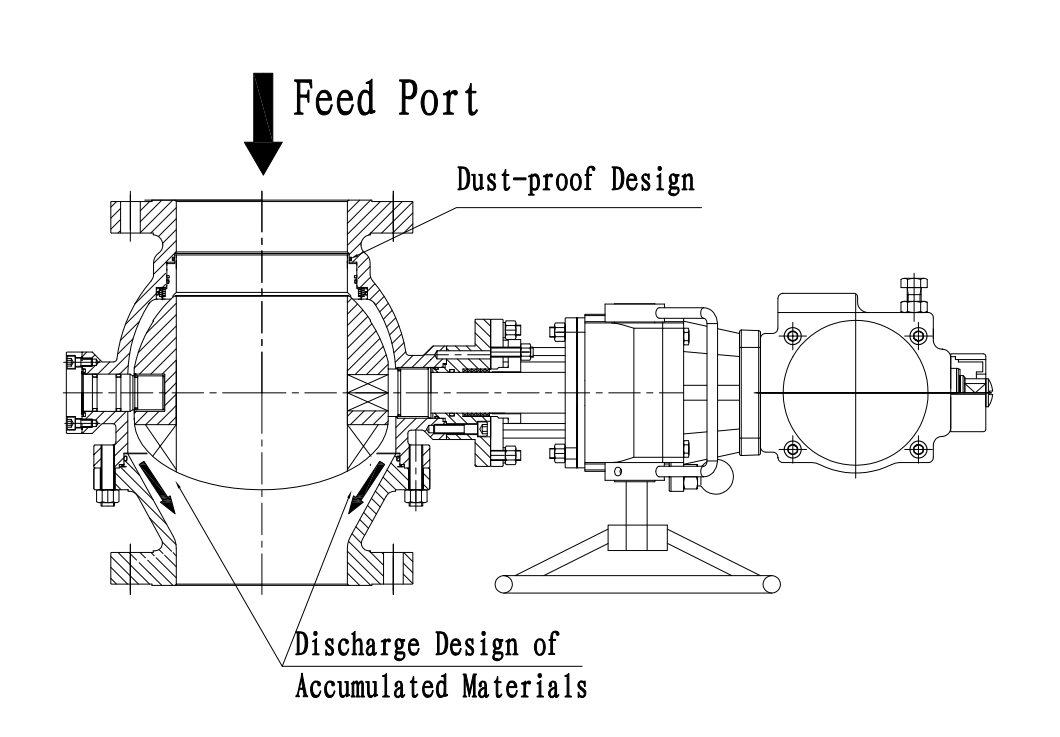

Therefore, it is suggested that the discharge valve and floating ball structure should be changed into the fixed ball structure of the front valve seal, and the back valve seat should be canceled, so that the valve cavity and the pipe behind the valve can be connected, so that the particles in the valve cavity can enter the discharge pipe from the position shown in the figure, and the backlog will not be caused. At the same time, the dust-proof design should be made for the front valve seat to ensure that the particles will not enter the spring position of the valve seat, and ensure the normal operation of the valve.